Newsroom

Indospace is Digitalizing Furniture Supply Chain Infrastructure for SME’s in Indonesia

June 29, 2022

Indospace is Digitalizing Furniture Supply Chain Infrastructure for SME’s in Indonesia

The rapid growth of Home & Living industry goods throughout the globe has increased drastically over the years. This increasing demand has highly fragmented the traditional supply chain ecosystem in Indonesia.

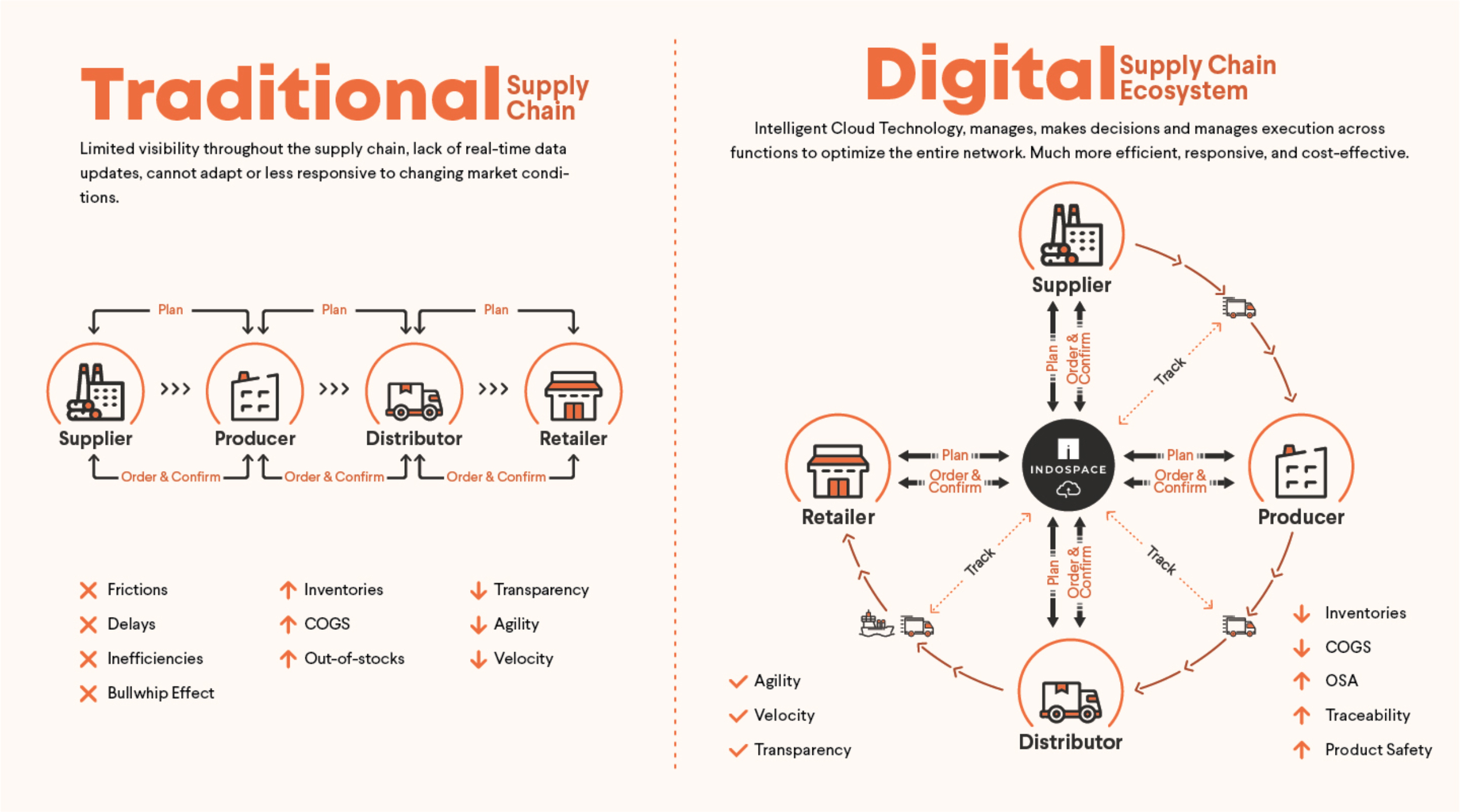

On the other hand, the furniture sector faces distinct challenges in the supply chain. Because of the size issues, without pre-planned strategies for warehousing and packing, the risks of the damages can increase. To minimize these risks of damage and keep the level of complexity in multi sectors in mind, the Indospace is working within a digital supply chain solution that has multiple benefits:

- Tracking the flow of the inventory through multiple supply chain stages

- The data changes are shared through cloud servers and databases

- They support enhanced consumer service and better product offerings

- Information remains centralised & safe

- Supplier reliability

Indospace has taken the challenge, to partner with small and medium-sized furniture manufacturers (SMEs) on the mission to digitalize and integrate the furniture supply chain. This collaboration will help us to fulfill demands on a global level. The digital supply chain will transform the furniture industry by making it easier to find and track inventory, manage production schedules, and bring more agility and responsiveness to customer needs & growing industry.

Changing the Traditional Furniture Industry

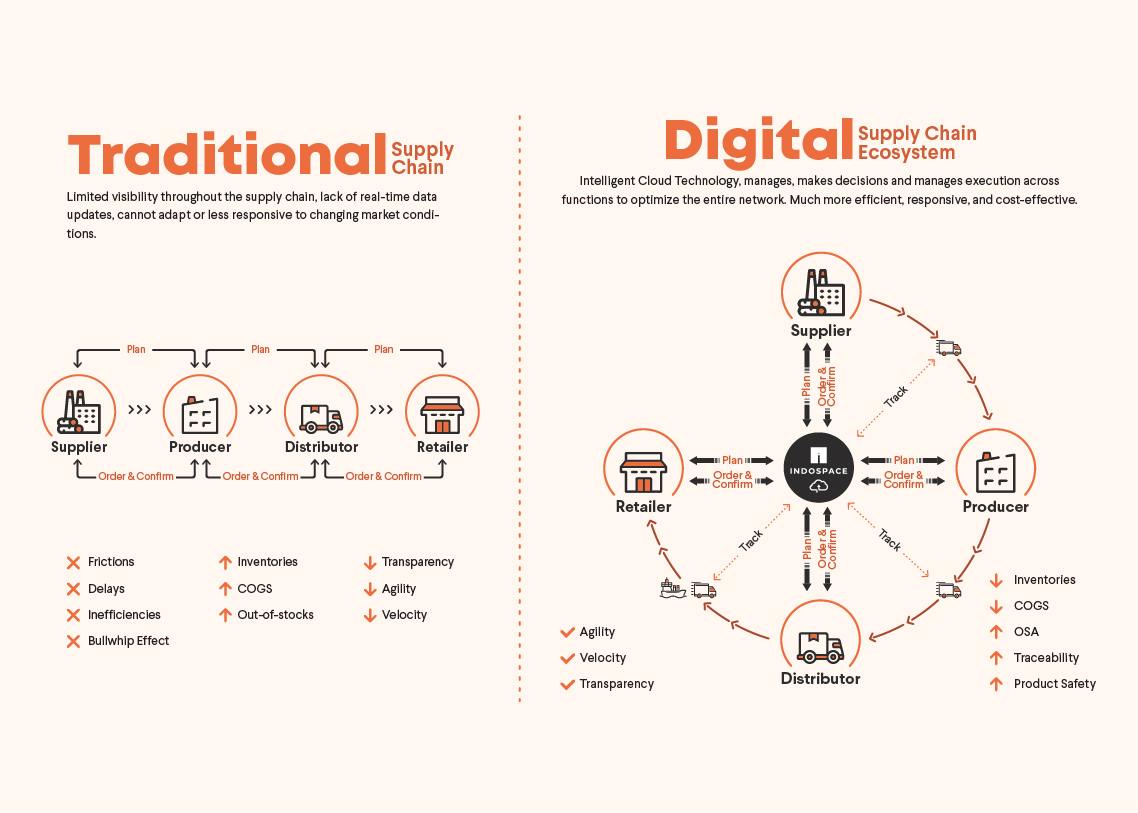

The traditional furniture industry is being disrupted by the rise of digital supply chains.

Industries like furniture have witnessed technological advancement in manufacturing processes but the end-to-end supply chain is yet outdated. It is completely offline which results in a lot of time and effort cost. Our vision is to disrupt this redundant business practice and provide ease of doing business. This is resulting in a more competitive marketplace and furniture companies are being forced to adapt or die. The companies that can adapt will be the ones that survive and thrive in the new digital economy.

The traditional supply chain doesn’t satisfy the requirements when it comes to keeping track and transparency of the whole process for a business that is spread across multiple areas. It can raise multiple challenges including:

- Lack of visibility

- Information sprawl

- Inability to maintain the safety and quality of your products

- Customer dissatisfaction

- Inadequate communication between parties

- Failure to track the product

- Lack of control of inventory in warehouses and stores

In the fast-developing world, supply chain management has entered into a new era of the digital economy. At any point tech stagnation can hamper the efficiency of the whole process. Therefore the necessity to digitalize the furniture supply chain management has increased.

Transforming Furniture Industry Through Integration of Digital Supply Chain

The pandemic has led to this digital acceleration, and it is a model that’s here to stay. Using the right technologies across the end-to-end supply chain empowers local manufacturers to make strategic decisions that help them become more agile and responsive to customer needs.

Driving Efficiency

Indospace is making an initiative to transform the whole supply chain ecosystem, resulting in more transparency, efficiency, and productivity. To fully digitalize each step of the furniture supply chain so data can flow seamlessly, providing end-to-end visibility for our customers, suppliers, and other stakeholders. This means they can stay ahead of the disruption at retail, and capture and share data across the entire value chain to enable smarter, faster, and more effective decisions, ensuring business sustainability.

Incorporating machine learning, IIOT (Industrial Internet of Things), big data, and AI will make logistics more efficient, sophisticated, and, most importantly, interconnected. For example, the use of sensors will allow components inside machines to self-check their status and reliability. AI and machine learning enable access to real-time data and analytics, giving firms better visibility into their supply chain. These types of technology will inevitably help businesses to minimize errors, maintain smooth operations, and manage assets efficiently.

The integration of these new-age technologies into the supply chain will drive better, faster, and smarter decision-making.

Accelerating Indonesian SMEs

We are on a mission… towards integrating vendors along the whole supply chain.

Digitizing the supply chain will provide businesses visibility into their operations. It will allow them to be more agile by having the ability to decide and respond quickly, especially in uncertain times.

- Digitalizing Supplier Management

- Purchase and payment management

- Automate data-driven decision-making

- Enhance quality and compliance while diversifying suppliers.

- Accelerate speed to market

- Future-proof supplier relations.

We are creating Cloud Applications that will support SMEs through digitization with production operations and financial management. The platform aims to increase the productivity of SMEs in Indonesia through significant technology adoption.

- Enable the visibility

- Avoid data wastage

- Facilitate greater profits